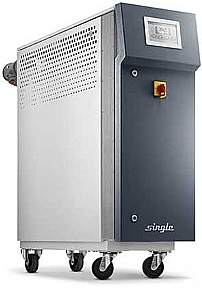

SMART 300 C Oil Type Mold Temperature Controller

SMART 300C Regulator temperature kalupa tipa ulja

PID temperature control in heating and cooling operation Hose breakage and leak monitor Sensor failure monitor Stainless steel tanks and heaters magnetic pump indirect cooling system Water level sensor measured via electrode automatic water supply Safety thermostat acoustic alarm Solid State Relay Process temperature return indicator PT100 process sensor

SMART 300 Series Technical Specifications:

PID temperature control in heating and cooling operation

Hose breakage and leak monitor

Sensor failure monitor

Stainless steel tanks and heaters

magnetic pump

indirect cooling system

Water level sensor measured via electrode

automatic water supply

Safety thermostat

acoustic alarm

Solid State Relay

Process temperature return indicator

PT100 process sensor

Options:

Serial interface TTY, RS232, RS485, Can Bus Profinet, Ethernet, OPC UA

frequency pump

Return pressure gauge

SMART 300 Oil Models

Max. Temperature Level 300⁰C

Heating Powers: 9 - 18 - 27 - 36 - 45 - 54 - 63 - 72 kW

Cooling Power: 80 - 115 - 230 kW

Pump Pressure: 6.0 bar

Pump Power: 1.0 - 4.0 kW

Pump Flow: 60 - 90 - 200 lt/min

Touch Screen Features and Control

PID control, ON/OFF control at 4 points

Temperature ramp in heating and cooling

Temperature control with external thermocouple, Type Pt1000

Heating with solid state relays

Auto Tuning

Pump pressure gauge

Return temperature indicator

Safety thermostat

Temperature and pressure graphs with file download option

Pump On / Off digital input

Secondary setpoint or forced cooling digital input

Analog outputs 4..20mA process and return temperature

Analog input 4..20mA Setpoint value

Language selection

Display in degrees Celsius / Fahrenheit. Bar / Psi. lit/min. / gallon/min

Control of equipment via VNC application

Save and load settings

alarm relay

Acoustic / visual alarm

alarm history

Configurable relays

Return pressure gauge (pressure units)

power cord

Options:

Serial interface TTY, RS485, RS232, Can Bus Profinet, Ethernet, OPC UA

frequency pump

Process flow screen

Interconnection with flow monitoring equipment

Return pressure gauge