Full Electric Injection Molding Machines

Potpuno električne masine za brizganje

Powerjet launched it`s first all electric injection molding machine in the year 2014. The newest generation version one is Version 3. These new series all electric injection molding machines have many advantages like saving about 65% energy and water compared to equivalent hydraulic machines. Parallel ball screw movements to ensure high precision and achieved short cycle times, Special optimize with mould protection, Clean for ideal production conditions and provide a quiet areas for perfonnel-intensive production & assembly zone, improve the internal stress characteristic property for plastic product, reduce distortion, improve the product surface. It not only reduces the cost of equipment, but also greatly extends the equipment life time.

Full Electric Injection Molding Machines

Powerjet launched it`s first all electric injection molding machine in the year 2014. The newest generation version one is Version 3. These new series all electric injection molding machines have many advantages like saving about 65% energy and water compared to equivalent hydraulic machines. Parallel ball screw movements to ensure high precision and achieved short cycle times, Special optimize with mould protection, Clean for ideal production conditions and provide a quiet areas for perfonnel-intensive production & assembly zone, improve the internal stress characteristic property for plastic product, reduce distortion, improve the product surface. It not only reduces the cost of equipment, but also greatly extends the equipment life time.

Why to Choose Full Electric Injection Molding Machine

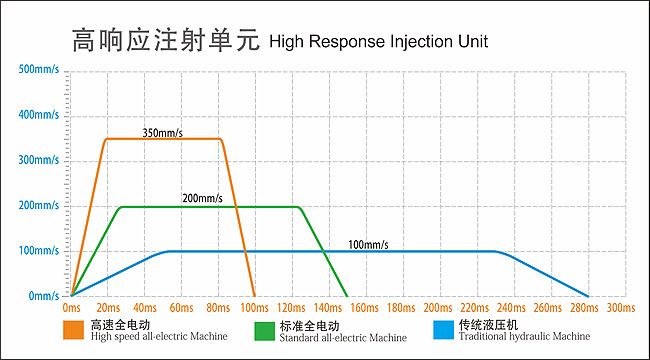

High Speed

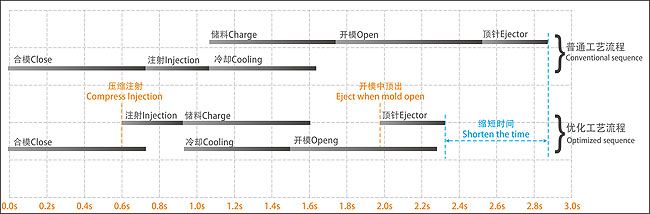

All electric injection molding machines are designed with synchronous movement, like mould closing and injection, mould opening and ejection is in action at the same time. It`s great help to shorten the circle time and easily realizing high efficiency production. Details please refer to below chart with a comparison of normal hydraulic injection molding machines and full electric injection molding moulders.

Quality Improved

All electric molding machine process is entirely repeatable and requiring no fine tuning to maintain exact specifications, thanks to the advantage of digital control.

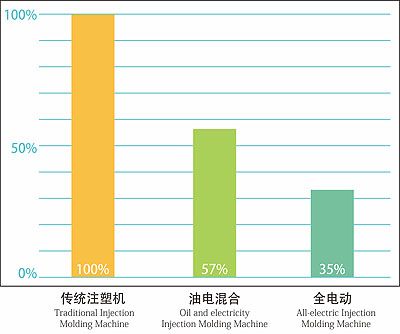

Energy Saving

With driven by servo motor, that is no energy lost of switching power to hydraulic and it`s temperature. This can help to save about 65% energy comparing to normal hydraulic injection molding machines.

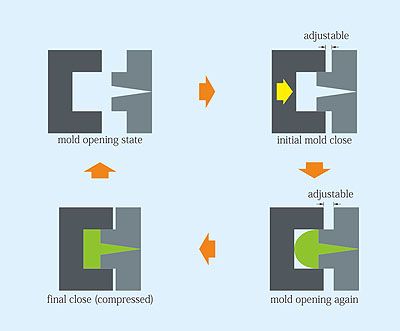

Program for Compression Molding

The compression cycle can be performed by easy programming. It's possible to freely programme the mold movements to synchronize with the injection movements.

This belongs to the low pressure molding technology category. It has the effect to improve the internal stress characteristic property for plastic product, reduce distortion, improve the product surface. With this control, the demand of injection force and clamp force parameters are truly optimized. It not only reduces the cost of equipment, but also greatly extends the equipment life time.

What is Full Electric Injection Molding Machines

KEBA Control System

- Latest Technology from KEBA

- Thanks to its powerful computer core, the KePlast i1000 control system is real-time-capable, thereby enabling a continuously controlled quality of production.

- For hydraulic standard injection molding machines

- Ultra-compact, single-board computer

- 7 to 12" TFT displays

- Closed-loop injection process including monitoring by means of injection graphic.

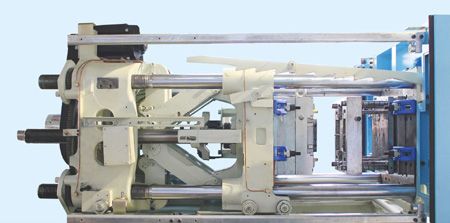

Clamping System

High circle speed, high precision, high rigidity, and high durability

High control precision of servo motor torque, and rigid connection of the ball screw and clamping system, correspondingly improve the mold opening/closing speed and position accuracy, and ensure an accurately platen moving thrust, and displacement deviation generated by platen movement inertia is under controlled, and the reliability and response accuracy of the action of low pressure mold protection is greatly improved. Safe security of using precision mold becomes better.

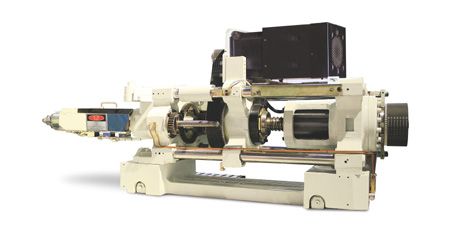

Injection System

High injection speed, high stability, high sensitivity, and high durability

Adopting four-column-frame structure and guided by four guide posts, the screw has an evenly balanced force during the process of injection, thus achieving steady injection molding.